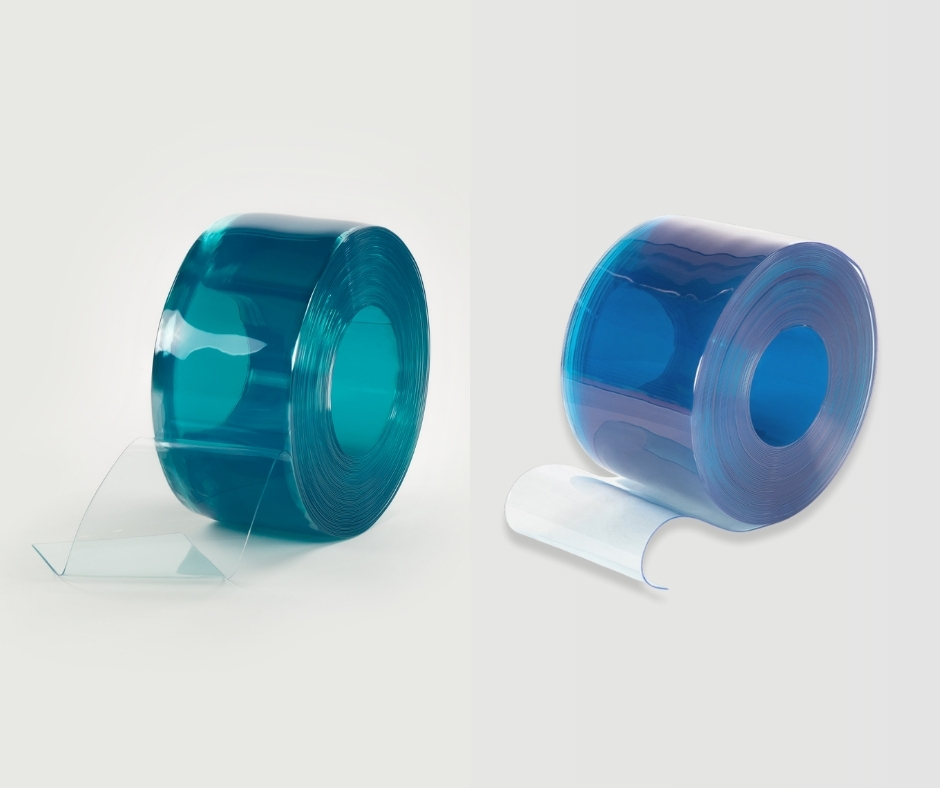

Super Polar vs. Polar: What’s the Difference?

Why Choosing the Right Cold‑Grade PVC Matters

Selecting the appropriate PVC strip grade is critical for maintaining efficiency and safety in cold chain operations. Temperature fluctuations, traffic levels and hygiene requirements all influence performance. This article compares Flat Super Polar and Polar PVC grades to help South African businesses make informed decisions.

Understanding the Temperature Range

Flat Super Polar is engineered for extreme cold, remaining flexible down to –60 °C. This makes it suitable for blast freezers and ultra‑low‑temperature storage where standard materials would crack. Polar grade performs reliably in temperatures down to –40 °C, covering most walk‑in freezers and cold rooms.

Flexibility & Mechanical Resistance

Super Polar offers superior flexibility and mechanical resilience thanks to its enhanced formulation. Its strips resist cracking and breaking even during heavy traffic in low temperatures. Polar grade provides good flexibility but is optimised for freezer conditions. Both grades feature high clarity for safe visibility.

Surface Finish & Wear

The surface of Flat Super Polar is smooth, allowing for perfect transparency. Polar also has a smooth finish and performs well in general applications where visibility and safety are critical. Both absorb some wear and tear depending on the loads going through and can scratch over time.

Energy Efficiency & Insulation

Both grades are designed to minimise energy loss by sealing doorways against warm air infiltration. Super Polar’s extreme cold resistance provides slightly better insulation in ultra‑cold settings like blast freezers. Polar still offers significant energy savings for conventional cold storage such as walk-in freezers or food production facilities.

Recommended Applications

• Flat Super Polar: Blast freezers, pharmaceutical cold rooms, deep‑freeze warehousing and any facility maintaining temperatures below –40 °C.

• Polar: Walk‑in freezers, refrigerated warehouses, food preparation areas and retail cold rooms operating between –40 °C and +0 °C.

Making the Right Choice

When selecting between Flat Super Polar and Polar, consider your minimum temperature, traffic volume and budget. For the harshest cold, Super Polar delivers unmatched flexibility and durability. For most applications, Polar offers a balance of performance and cost‑effectiveness.

7. Maintenance & Longevity

Proper care extends the life of both Super Polar and Polar strips. Regularly inspect the strips for nicks or cloudiness and replace individual strips as needed. Clean the surfaces with mild detergent and warm water to remove dirt and grease; avoid harsh chemicals that can degrade the PVC.

8. Cost Considerations & Return on Investment

While Super Polar typically carries a higher upfront cost due to its enhanced low‑temperature formulation, its extended lifespan and superior insulation can lead to lower energy bills and fewer replacements. Polar, on the other hand, offers a more economical price point and delivers solid performance in standard cold storage applications. Evaluate your energy usage, maintenance schedule and replacement frequency when calculating the total cost of ownership for each option.

Conclusion

Investing in the correct PVC grade will prolong strip life, enhance safety and reduce energy costs. Maxiflex partners with Extruflex to supply both Super Polar and Polar solutions, ensuring South African facilities get the ideal product for their specific requirements.